Weld inspection simple. The other way around!

Routine examinations on microscopes require time and experience. The samples must be prepared, mounted and properly focused for the exposure. The subsequent measurement must be carried out consistently.

The InversController enables components to be inspected after just a short grind without further preparation. Due to the inverse support of the test objects, the images are calibrated within seconds in the Imagic IMS software and the guided measurement process is seamless and easy to use.

Time saving with every single image acquisition

The test object is simply placed inversely on the glass pane and there is no need for focusing. Due to the fixed magnification and the defined distance, the image is always automatically calibrated. The integrated LED ring light also ideally illuminates the sample.

High quality BUT cost efficient

Due to the consistent focus on a specific routine task, the InversController is extremely cost-efficient despite the use of high-quality components compared to classic microscopes.

Figure:

Weld seam measurement with or without template also on live camera image1

Easy operation thanks to tailor-made and guided processes

With the Imagic IMS software, routine tasks can be mapped in a standardized way and customized measurement templates can be stored. Both increase ergonomics and also allow less experienced personnel to perform the tasks correctly.

The seamless transfer of image and metadata to the Imagic IMS database enables effortless documentation and reporting. All data, including measurements carried out, are also directly available to other users for further evaluations and controls.

1: All images are icon images. The final design may differ.

- Objective, brand-independent advice on hardware products

- Saving time with every image capture

- Easy operation thanks to guided processes

- Attractive price-performance package by focusing on a optimal workflow

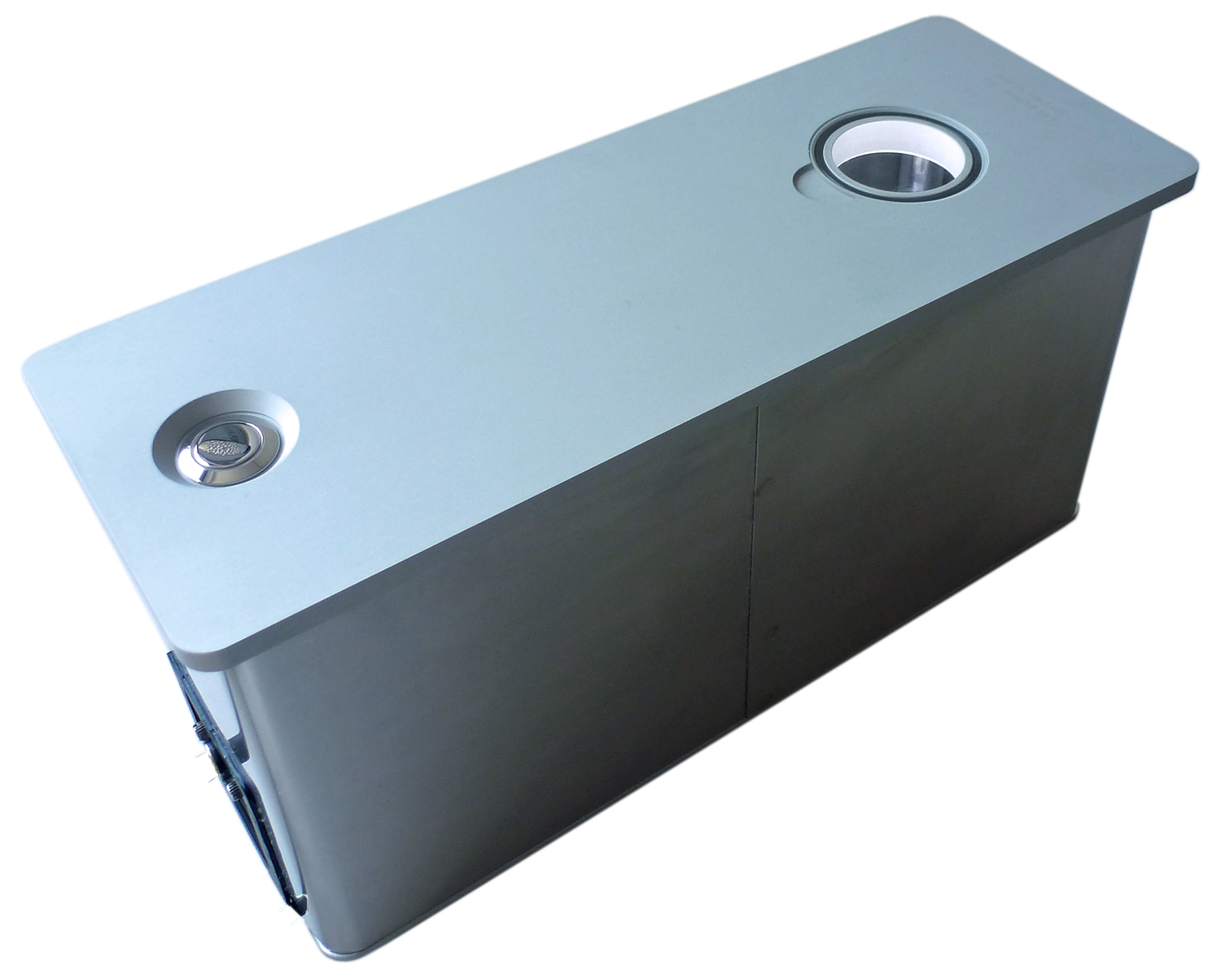

Figure:

The handy InversController1

Find out more about how you can optimize your workflow in production-related inspection and contact us for personal advice or a non-binding live demonstration.